Load cells, torque sensors and multi-axis sensors are manufactured with one of the most advanced technologies in the sensor industry. They support emerging technologies, innovate established ones.

-

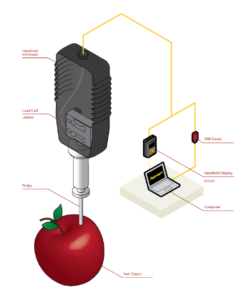

FRUIT/VEGETABLE PENETROMETER

Application Summary

Whether you’re stocking fruits and vegetables for controlled ripening or you’re a farmer in a field, you need a way to accurately quantify maturity along with the experience and knowledge that comes with the job.

Maturity can be quantified as the force needed to dent or pierce the pulp of fruits and vegetables.

This requires a device such as a penetrometer equipped with a compact load cell.

How it works

-

An OEM LSM250 or LSM300 load cell is mounted inside a handheld unit with a penetrating tip attached.

-

An operator then presses the assembly into the pulp of the fruit or vegetable.

-

The load cell measures the force applied throughout the entire process that is sent to the IHH500 digital portable display or the USB220 high-resolution USB solution connected to a laptop running our SENSIT software

-

The IHH500 and USB220 track the applied force and show the maximum load that was applied.

-

The maximum load is then correlated with the tables to determine the maturity of the sample.

-

The LSM250 and LSM300 provide up to 1000% axial overload protection (2.2 lb to 25 lb) to mitigate operator error.

Products in use

An OEM LSM250 or LSM300 line load cell paired with instrumentation (IHH500, USB220).

-

DOSAGE WEIGHING

Application Summary

Known for its resistance testing capabilities, FUTEK’s series of loading buttons can be used in the manufacture of batch weighing applications.

How it works

-

Using loading buttons, the contents of a small-scale industrial silo/container can be monitored.

-

Installed at the base of each leg of the container, these compression-based loading buttons will measure the contents of the container as it waxes and wanes.

-

As an in-line load cell, FUTEK’s LLB series requires a direct vertical load on its charging surface, the button, to obtain accurate measurements.

-

Data from each load cell can be collected and transmitted via an adder junction box, such as fuTEK 2–4 channel IAC200 adder junction box , to a digital display. Both the FUTEK IPM650 panel mount display and the IHH500 smart digital handheld display are compatible with this test platform.

-

By equipping the platform with FUTEK’s IPM650 or IHH500, alarms and/or relays can be used to automate the process.

-

Operators can also use FUTEK’s USB solutions, a USB module per load cell, to transmit data directly to a PC.

-

FUTEK’s SENSIT ™ test and measurement software can enhance the test platform, allowing the operator the ability to collect and graphically represent all data live.

Products in use

A charging button (LLB Series) is used for each support gasket paired with Instrumentation (USB Solutions, IAA Series, IHH500 and IPM650).

-

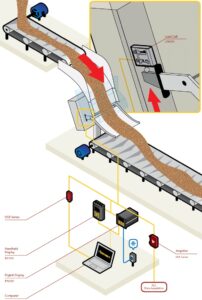

MASS FLOW METER

Application Summary

Using an adapter button, the FUTEK LSM series load cell is competent to measure the mass flow of solid particles in any process line.

How it works

-

FUTEK partners with several manufacturers of control devices to design and develop OEM load cells to constantly measure particle flow.

-

FUTEK’s LSM series are side-mount load cells competent in tension and compression measurements with built-in overload protection.

-

This application concept illustrates the LSM load cell attached to a counterweight assembly, in which the force detection point is coupled with the plate surface.

-

The measurement output can be carried to an amplifier, a digital display or transmitted via USB technology.

-

Both the digital display and the USB path allow operators to make additional use of FUTEK’s SENSIT ™ test and measurement software, in which they can experience the results of data and graphics recording.

Products in use

OEM load cell (LSM series) paired with instrumentation (IAA series, IPM650, IHH500 and USB solutions).

-

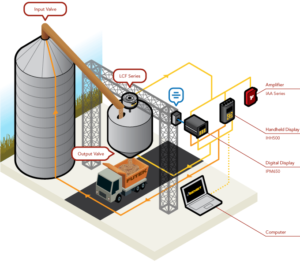

TANK DISPENSING

Application Summary

Tank dispensing is based on the contents of the container, both inbound and outbound. This application uses a full load cell system to ensure equitable distribution.

How it works

-

In this application, a silo feeds the grain to a dispensing vessel, while an outlet valve releases the grain to the conveyor truck below.

-

To monitor the contents entered and emitted, the application engineer has installed a load cell of the FUTEK LCF series above the dispensing container.

-

As grain is added or removed from the container, the FUTEK LCF series load cell will measure the distribution ratio of the grain as it leaves the container.

-

To ensure an equitable distribution of grain among transport trucks, FUTEK instruments (IHH500 and IPM650) are programmed to activate the outlet valve to release an equal amount each time.

Products in use

An LCF series pancake load cell paired with instrumentation (IPM650, IHH500 or IAA series).

-

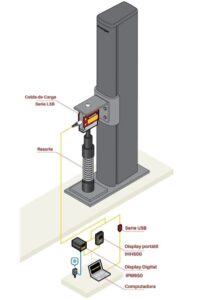

SPRING TEST SYSTEM

Application Summary

Spring test systems are ideal for high-volume production, quality control, inspection and design. In this automated spring test, an S-type load cell is placed in the spring test column to measure the strength of the spring in relation to its position.

How it works

-

During research and development, the automated spring tester can be configured to extend or contract the spring.

-

Futek’s LSB series load cell is fixed to the test column to measure the tensile or compressive force when the spring is expanded or contracted.

-

These force measurements can be transmitted to a computer for analysis with Futek’s USB solutions.

-

This information can then be used to determine or verify spring flexibility using Hooke’s law.

Products in use

The LSB series load cell with USB instrumentation.

-

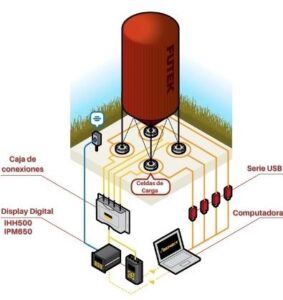

SILO MEASUREMENT

Application Summary

Measuring the contents of any tank, silo or industrial hopper requires a robust and accurate system. The use of multiple high-capacity load cells for silo measurement together with powerful instrumentation can constitute an effective platform.

How it works

-

Four pancake load cells of the LCF series have been installed at the base of the poles of this silo (silo load cell).

-

Depending on the operator’s preference, two instrumentation media can be used to retrieve the measurement data of the silo content (silo load cell).

-

The first method is to use FUTEK USB Solutions. Each LCF series pancake-like load cell is paired with a USB module that can transmit live data to a PC using FUTEK’s SENSIT test and measurement software.

-

The second method is to connect each pancake load cell of the LCF series to FUTEK’s 2–4-channel IAC200 adder junction box , which will collect the collective load of each load cell and then transmit that output to a display (IHH500 or IPM650).

-

These methods can also be automated to sound an alarm or send a notification when the weight of the silo reaches a specific mass (silo load cells).

Products in use

Four LCF series pancake load cells paired with instrumentation (2–4 channel adder junction box IAC200, IPM650,IHH500 or USB solutions).

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation