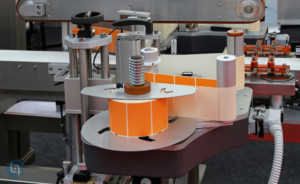

Industrial labeling

The labeling of products in the industrial sector plays an essential role, since labeling our products ensures that they carry our brand, descriptions, and regulatory complements.

In a few words I can say that the labeling process must be taken with high importance in a production line, and likewise rigorously monitor this process.

The real challenge begins when you must monitor labels and account for a high demand for products, which requires a high-speed production line, and this means that products are labeled at high speeds, even so fast that you will not be able to distinguish where it starts. and where a label ends.

You will find yourself in the need to find a unique device, truthful and capable of working at the highest speeds that these high-demand machines can go. This is where we answer how to optimize this process and what product is up to the task.

Optimization of industrial labeling

Optimizing now will only be possible if you have the ideal device to monitor in the environments with the highest demand for product labeling on the production line, and also giving your process a competitive advantage that goes hand in hand with obtaining the optical advantage.

The MINI LABEL EYE ® is a special purpose gap or slot sensor optimized for detecting adhesive labels on the web.

GET THE OPTICAL ADVANTAGE!

The specially designed optics of the MLE greatly reduce the sensitivity to web flutter. High-intensity IR LED penetrates thicker backing material and reduces temperature drift.

A staggering 35 microseconds allow the MLE to keep up with even the fastest high-speed rewinders, plus it features a large, bright LED indicator that is easily seen from all angles, it’s easy to set up with an automatic setting of an I touched.

This miniature sensor can fit in many small spaces with only 10mm width. Integrated bracket fork design makes mounting easy.

Watch 3D model

https://www.logicbus.com/Tri-Tronics_bymfg_115-7-1.html

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation