Measuring Hot Food Temperature Through Glass Jars

Best Solution for measuring hot food temperature

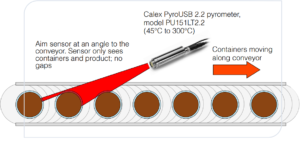

Infrared temperature sensors are ideal for measuring the temperature of hot food products through glass containers like the new Calex PyroUSB.

After a food product is filled into glass jars, samples are usually taken from the production line and manually probed to check the product temperature. The PyroUSB now makes it possible to check product temperatures without taking samples from the production line, and without even touching the samples at all.

Glass is highly transmissive to infrared radiation at wavelengths around 2.2 microns, so the PyroUSB can effectively see though a glass container and measure the temperature of the food product inside. This model is capable of measuring the temperature of high-emissivity targets, such as food, as low as 45°C.

Application tips for measuring the temperature of hot food products

The emissivity setting should be adjusted to compensate for the small amount of energy absorbed by the glass. The required emissivity setting will depend on the thickness of the glass, as more infrared radiation is absorbed by thicker glass.

Position the sensor as close as possible to the target to achieve the smallest possible measured spot size. The PyroUSB sensor should be positioned level with the containers if possible, and aimed at an angle to the conveyor so that its field of view is always filled with product containers. This way, the sensor cannot see any gaps.

Provided the sensor cannot see through gaps in the stream of containers, the speed of the conveyor will not affect the accuracy of the measured temperature. The selectable 0-20 mA or 4-20 mA output of the PyroUSB is ideal for connection to existing process instrumentation, or Calex can provide a suitable indicating controller. The USB connection also provides temperature monitoring, alarm and data logging via the included CalexSoft software.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation