For reliable and efficient operation of the grid, power substations which transform, switch, and distribute electrical power to users are interconnected not only electrically, but also by a network of communication links and control systems. These networks are designed to enable real-time monitoring, control, and protection of the power system, allowing operators to respond quickly to changes in power demand or disruptions to the grid. A modern substation communication network follows the IEC 61850 Standard to provide interoperability between various equipment, and enables advanced functionalities such as wide-area protection and control, fault location, and disturbance recording.

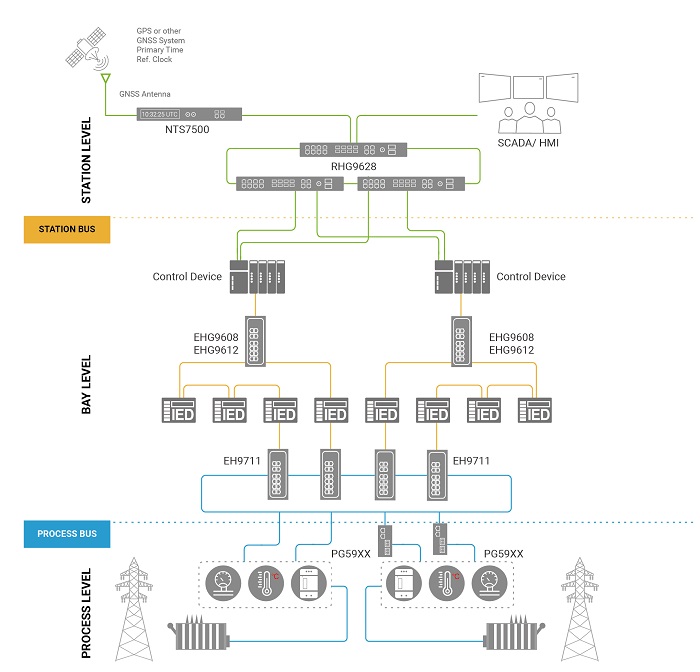

The IEC 61850 Standard defines substation communication in three levels: Process Level functions interface with electricity processes like switching and monitoring. These processes are controlled from the Bay Level by intelligent electronic units (IEDs), such as protection relays, meters, and controllers. Data acquired from the process level also passes through the bay level to inform station actions at the Station Level, or to be further aggregated and sent to monitoring systems like SCADA.

Several aspects must be considered to achieve maximal substation network reliability:

Electromagnetic compatibility (EMC) is definitely one of the first priorities to think about when building a substation network. Situated near power equipment and cables, devices in substations require better EMC than normal industrial facilities do. IEC61850-3 defines the construction, design and environmental conditions that substation devices must meet, and only when fully compliant and certified does ATOP present a device as “for substations.”

Rugged housing that withstands demanding weather and heavy use is also indispensable in power applications. Especially with the rise of clean energy, substations are often located in remote and severe environments, so ATOP IEC 61850-3 certified devices make sure to deliver optimal performance even under harsh temperature and humidity conditions. The Gigabit Ethernet switch EHG96xx series, for example, has wide operation temperature spanning -40°C to +85°C.

Redundancy is important to ensure that the substation network can continue to operate even if some equipment or systems fail. This can be achieved through the use of redundant power supplies, redundant control systems, and backup communication systems.

The EH9711 managed switch, designed specifically for substation access, enables both power and communication redundancy through dual power inputs as well as ring topology support. In the event of node failure, ring topologies like RSTP and ERPS allow traffic to self-recover in milliseconds. In addition to RSTP and ERPS, the Gigabit backbone switch RHG9628 also supports HSR/PRP to guarantee zero packet loss for critical substation information.

Interoperability, as mentioned earlier, is one of the key points of IEC 61850. Substations contain a variety of devices that use different protocols to communicate with each other. Some may even be legacy or proprietary. Protocol gateways act as a bridge between these different protocols, allowing devices to exchange information and operate together seamlessly. ATOP takes this concept a step further with diverse media options, such as optional SFP slots in PG5904D, or cellular connections in PG5901B.

Precise timing, as first mention, may not seem closely related to power transmission—what is a nanosecond’s difference in receiving electricity? But in truth, the impact of timing in substations is more critical than many imagine. Accurate synchronization of devices enables control systems to operate more efficiently and effectively, reducing the risk of errors or failures. All events on the network are logged with the same time reference, and protection devices can operate in the correct sequence, regardless of where they occur. This not only maintains the safety and reliability of operations, but also allows determination of the exact sequence of events, which is crucial in performance control and troubleshooting.

ATOP offers comprehensive solutions for precise timing in the nanosecond level, from grandmaster clock NTS7500, which syncs with a GNSS reference, to a range of powerful switches that support precise hardware-based boundary and transparent clocks, assuring the accuracy of events throughout the network.

Cybersecurity has been a growing focus of substation networks in recent years, as the more interconnected and digitized these systems grew, the more vulnerable they became to cyberattacks which could potentially cause significant damage. High availability requirements, wide geographic spread, and often legacy equipment pose unique challenges in securing power networks.

ATOP cybersecurity is certified for IEC 62443-4-1 and in the process to receive IEC 62443-4-2, which means that all products are developed and created with the highest awareness of cyber-risk consequences. Our substation solutions encompass numerous forms of protection including access control, network segmentation, and encryption, to serve different scenarios and needs.

Finally, a reliable network benefits from remote management and monitoring. ATOP solutions come with user-friendly management software that allow real-time visualization of topologies, remote control and troubleshooting, smart alarms, and more. Operators can quickly and easily onboard new devices, scale network systems, find bugs and errors, and resolve issues from off site, improving efficiency while lowering the costs of maintenance.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation