Application Summary

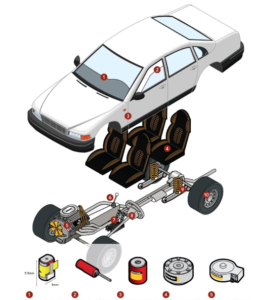

New technologies and features are bringing new challenges to automotive application design. This makes rigorous durability and fatigue testing even more crucial. Automotive durability testing supports the evaluation of vehicles, subsystems, and components from component manufacturers and OEMs to determine the expected life of the product.

Testing uses real-world movements and forces to evaluate and validate design and improve quality. FUTEK supports automotive OEMs and subsystem manufacturers by offering a wide range of sensors optimized for automotive testing (automotive sensors).

In addition to complete vehicles, automotive durability testing evaluates components including the engine, suspension, gear lever, brakes, steering wheel, windows, chassis, frame, infotainment system, door and seat hinges, interiors, and suspension.

Capabilities include cyclic fatigue testing, functional safety, deflection, electrodynamic vibration, voltage measurements, and more.

Automotive testing capabilities of FUTEK sensors

- Durability and Performance Test;

- Fatigue and Vibration Test;

- Torsion and Rotation Tests;

- Multi-axis durability test;

- Functional safety;

- Validation of electromechanical control loop.

Compliance with automotive industry standards

FMVSS 118: Electrically operated window systems, partitions and ceiling panels;

ASTM D3574 B1 / ISO 2439: Seat foam indentation force deflection (IFD);

SAE J2909: Dry and wet braking distance test procedure for light vehicles (brake test);

ECE R13H: Provisions for the braking of passenger cars;

ISO 7975: Passenger cars – Braking on a turn – Open loop test method;

ISO 13849-1:2015: Safety of machinery – Parts of safety-related control systems;

ISO 26262-1:2018: Road vehicles – Functional safety

How it works

1. Touchscreen feedback:

By incorporating load cells to measure contact force, the car’s on-board computer can confirm correct command inputs on the display.

2. Pressure on windows and roof of the car:

By using the load cell for pinching, car manufacturers can check the force that the windows and roof of the car resist. They also ensure that the product can meet the life cycles that were calculated in design.

3. Torsional hardness of automotive hinges:

When we talk about hinges, the torque required to open or close the door or panel is essential. The energy required depends on the weight of the door, the arc of distance that runs through the door and the position of the hinges.

4. Seat durability:

In the automotive industry there are already robots that are used to make test cycles on seat materials. It is tested with conditions that emulate people of all ages and sizes.

For this, a pancake-type load cell can be used, placed on the seat and durability tests can be carried out.

5. Engine Dynamometer:

Manufacturing engineers use dynamometers to measure power output and thereby measure performance factors such as horsepower, acceleration, and mileage.

6. Gear Lever Test:

The MAU300 gear lever sensor is another unique product designed for the automotive industry and is ideal for shift lever drive force measurement applications in automobiles.

Designed to test the Fx and Fy loads that take place during gear shifting, the MAU300 is designed for manual use/human testing.

7. Brake pedal acceleration and force:

Brake system testing is normally carried out during various stages of the manufacturing process. It starts at the initial development stage, followed by resistance, laboratory and track testing, and continues through the production process to ensure additional quality.

Using LAU220 pedal force sensors (also known as brake load cell), automakers can verify the safety and reliability of their car’s braking mechanics. Pedal force sensors (vehicle sensors) are designed to measure the load applied to the brake, accelerator and clutch pedals during acceleration, deceleration and transmission changes.

8. Steering wheel:

Steer-by-Wire (SbW) technology in the automotive industry is the use of electronic devices, actuators and algorithms to replace hydraulic and mechanical connections between the manual steering wheel and the road.

During the product validation phase, the QMA148 low-profile thrust and torque sensor provides QA and control engineers with the right tools to measure rotational torque applied to steering controls.

9. Suspension Strap – Front Suspension Frame Fatigue and Durability Testing:

The complex multi-point suspension systems used in high-performance vehicles require the use of models and simulations to ensure compliance under load. However, the final step to validate the live test simulation model.

To achieve this, the load cells are placed in line with each suspension arm, providing data on the load passing through each arm, accurate measurements of steering load and indirect grip of the front tyres that allows the suspension system to be adjusted to optimize performance and handling.

10. Brake caliper:

In wired brake systems, central controllers require accurate information about the clamping force between the brake pad and the disc based on the displacement of the pad, which is normally indicated as the characteristic curve of the caliper. Due to aging, temperature and other environmental variations, the characteristic curves of the caliber vary over time.

Therefore, automatic calibration of the caliper in real time is vital for high-performance braking action and vehicle safety. In addition, during design validation, engineers use a force measurement system to validate and calibrate the cable brake closed-loop systems. The QLA307 washer-type load cell has a low profile and can withstand massive loads, and is commonly used for the Caliper load cell for brake pad testing.

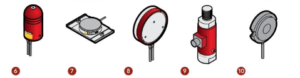

Products in use

- QLA414 Nano Sensor – Touch screen feedback;

- LMD300 Pinch Force Sensor – Pinch Test for Window and Ceiling;

- TFF400 Jet Torque Sensor – Hardness in Hinge Movement for Car Door;

- LCF456 Pancake Load Cell – Seat Durability Tests;

- LCF400 Universal pancake load cell – Motor dynamometer;

- MAU300 Multiaxial sensor – Shift lever hardness;

- LAU220 Pedal Force Sensor – Force on acceleration and brake pedals;

- QMA148 Torque and Thrust Sensor – Steering Wheel Tests;

- LCB400 Bar type load cell – Suspension test;

- QLA307 Washer type load cell – Brake caliper test.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation