The lithium battery industry in recent years has developed rapidly throughout the planet. Thanks to the continuous introduction of new industrial policies, this lithium battery industry has taken a new step.

China has been a country that has developed this industry in a very good way. According to data from last year, the first quarter of 2021, the lithium battery industry achieved an operating income of more than 80 billion yuan (Over 12 billion dollars), an increase of 79% compared to 2020.

According to statistical data, China’s lithium battery industry is expected to exceed 640 billion yuan (over 100 billion dollars) by 2025. Lithium batteries have become an essential part of electronic equipment such as: mobile phones, tablets, battery banks, drones, electric vehicles, portable devices, etc.

The industries have increased their production capacity due to the aforementioned points. However, lithium batteries in the production process will inevitably produce some surface damage, such as scratches, bumps, etc., which pose a serious threat to battery safety.

In the battery electrode production process, it will cause defects in the positive and negative electrodes due to the coating machine.

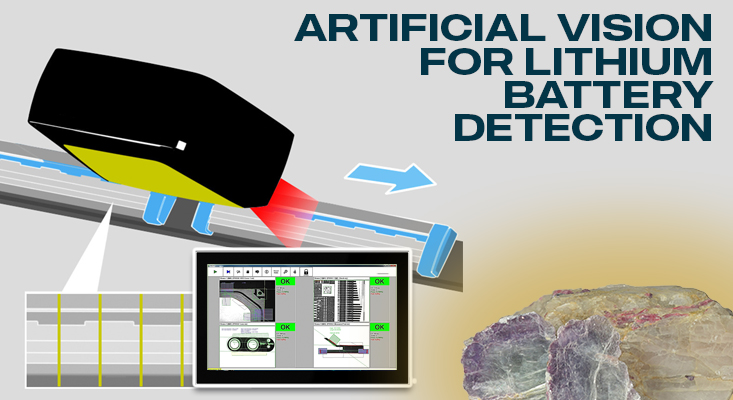

ARTIFICIAL VISION POWERS THE MANUFACTURING OF LITHIUM BATTERIES

From the structural point of view, the lithium battery manufacturing is very simple: the battery cathode (positive charge) and anode (negative charge) electrode are stacked alternately, each layer with diaphragm, electrode between liquid or solid electrolyte .

However, the actual production process is quite complex and delicate. The thickness of the electrode coating has a great impact on the performance and even the stability of the battery. Especially in the large-scale production mode, any scratches, dew sheets, bubbles, wrinkles, dark spots, bright spots, missing materials and other defects caused by the materials of the battery, cells, PACK packaging and other links will seriously affect the performance and quality of lithium battery products.

INSPECTION OF THE PROCESS FOR QUALITY IMPROVEMENT

The quality inspection of the lithium battery production process has become a key point. Machine vision has changed the lithium battery production mode with extremely high detection efficiency, detection accuracy and super stability.

SOLUTIONS PROVIDED BY TAICENN AND ITS PRODUCTS

TAICENN Panel PC: TPC-DCP215K will serve for machine vision process and control integrated to lithium battery detection equipment, such as lenses, industrial cameras and image processing units, combine with image processing software to replace artificial vision for the acquisition, recognition and judgment of information.

This Panel PC:

- Improve detection efficiency and reduce labor costs.

- The operation is simple and uncomplicated, and the system stability is strong.

- You can track the defect database in real time for intelligent analysis.

FEATURES OF THE TPC-DCP215K

- 21.5″ widescreen TFT LCD screen, LED backlight, Full HD 1920*1080.

- Intel Celeron 3855U or Core i5-7200U processor.

- Multipoints (max. up to 10 points) Projective capacitive touch, EETI controller.

- Aluminum and magnesium alloy, anodized treatment, Modular design.

- DC 9~36V, with overcurrent, overvoltage and polarity protection.

- 4*GLAN (supports PoE), 2*USB3.0, 2*COM, 1*VGA.

- Slim, fanless design, panel mount, VESA, IP65 front protection.

Check out this link and read the full information for this Panel PC, it has many characteristics that will help you in artificial vision applications, and more industrial processes.

IN THE END

The exploitation of the lithium battery market is just a dew on the development of the manufacturing industry of China and the whole world. When the current industry grows, what new technologies and new products will machine vision use to overcome application limitations and promote the intelligent and digital development of China’s manufacturing industry? We do not know yet. But in any case, TAICENN and Logicbus will always continue to push new technologies in all fields.

Contact us

Email: sales@logicbus.com and support@logicbus.com

Whatsapp: +1 619-600-1015

Online chat: Start conversation