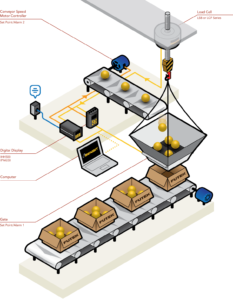

FUTEK’s load cells are designed to fit applications like industrial automation container filling and/or weighing. A force sensor is installed in an automation line to help monitor equal distribution through packaging using automation load cells.

How it Works

- To ensure equal quantities of a product are distributed into each box, a load cell in conjunction with specific instrumentation has been installed.

- The load cell itself is connected to the hanging distribution container to monitor the weight of each load released into each box.

- Once the upper conveyor belt has dispensed enough product into the distribution container, the instrument connected to the load cell will trigger a relay causing that upper conveyor to stop.

- This then immediately causes another relay to trigger, which releases the gates of the hanging distribution container allowing its contents to fill the box below.

- As soon as the gates of the distribution container close, the upper conveyor resumes motion, allowing for this automation process to begin again.

Products in Use

Load Cells (LSB or LCF Series) paired with Instrumentation (IHH500 or IPM650).

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation