Load cells are normally used for monitoring applications, not for nothing its best known application is its use in scales. Although clearly this application will always be present in the commercial branch, in the industrial branch load cells have a much more complex application.

It is not easy to carry out a control with a type of sensor, as there are too many external factors such as temperature, humidity, dust or human error; for this reason the control is usually done with high precision sensors and response time.

Although not apparent, load cells usually do not have a high sampling rate, which greatly impacts their response time. We can have the fastest and highest resolution controller on the market, and still fall victim to slow readout and improper operation of the control mechanism. An important part of the control, in addition to success in terms of production, is the protection of the system itself; there are multiple actuators that work according to the sensor information and a simple time variation in a measurement can lead them to fail in their task.

So what do we need to review before the acquisition of a load cell for process control?

Natural Frequency.

While not a value that is easy to find in many brands, it is worth investigating the natural frequency of the sensor to be used. This allows us to know how often the sensor can update its electrical output through its mechanical excitations.

A high natural frequency will not only allow us a spectacular control, but it will also allow us very good readings in impact or reflection applications.

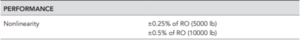

Linearity

This factor is very important because no sensor scales in a perfectly linear way, but a small variation within each parameter must be taken into account. Note that there is some linearity even with that variation, so we should not allow sensors that slowly deviate from the expected value. This simply indicates that the sensor is damaged.

Hysteresis

![]()

Once the linearity of the cell is recognized, it is necessary to recognize and consider the error value or variation that a sensor can have on the same measurement. For this it is necessary to know the hysteresis, which corresponds to the variation that can have on the same measurement of the same applied load. This value is common within the specifications of a load cell.

With these known values and in acceptable selection ranges it will be possible to create a weight-controlled system.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation