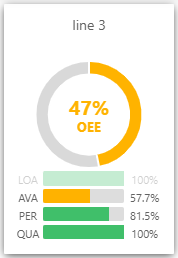

What is OEE? What does OEE mean? OEE, or Overall Equipment Effectiveness, is a key manufacturing metric that considers different components of the production process: Availability, Performance and Quality. After analyzing these factors, the result is expressed as a percentage.

OEE Percentage and what it tells us

This OEE percentage is like a snapshot of the current production efficiency for a machine, line or cell.

Manufacturing a product is a complex process. Without metrics and guidelines, it’s easy to lose control and have your business become production driven.

OEE is a tool that combines multiple aspects and manufacturing data to provide crucial information about the process. By analyzing and calculating data, it also serves as a framework for root cause analysis. Through a documented process that combines underlying data, OEE provides specific information about the process. The entire manufacturing team, from assembly technicians to financial personnel, can use this data to understand the current state of the manufacturing process.

OEE Framework

OEE is a very simple metric to immediately indicate the current state of a manufacturing process, but it is also a complex tool that allows you to understand the effect of various problems in the manufacturing process and how they affect the entire process.

By having a predefined framework of the impact of machine availability, throughput and quality, OEE provides a framework for tracking underlying problems and root causes. It also provides a framework for manufacturing process improvements. By utilizing key OEE concepts, such as the “Big Six Wastes” revealed by tracking OEE, inefficiencies can be understood and efficiency can be improved.

The 4 components of the OEE framework

These components are:

- OEE

- Availability

- Performance

- Quality

Availability refers to the machine or cell being available for production as scheduled. Basically, when a process is running, it is generating value for the end user. When it stops, it is generating a cost with no associated value. Whether due to mechanical failures, primary materials or operator problems, the cell or machine is either producing or not producing. By comparing scheduled run time to actual run time, the availability component of OEE allows you to determine lost production due to downtime.

Performance is determined by the amount of waste created by running at a less than optimal speed. By comparing actual cycle times to ideal cycle times, OEE allows you to determine how much production was lost due to cycles that did not meet the ideal cycle time.

Quality focuses on identifying the time wasted in producing a product that does not meet quality standards. By comparing the number of good products to rejected parts, it exposes the percentage of time that actually adds value in producing a good product.

Top 5 benefits of using Auk Industries to measure OEE in production

A world in which Industry 4.0 and digitalization are designed and built for people: that is the vision of Auk Industries. To achieve it, Auk Industries, in company with Logicbus, helps remove the obstacles and complexities facing industrial organizations in digital transformation, a top strategic goal cited by many, but achieved by few. Quite simply, the best system for measuring the OEE indicator.

On its own, OEE provides data about your manufacturing process. Companies that use Auk Industries as a metric have found success by combining it with their overall lean manufacturing plans, which on their own, did not achieve 100% of what was expected. By using Auk Industries with these plans, the benefits are significant:

- Directly link production efficiencies to fiscal reporting.

- Reduce investigation time for root cause analysis

- Shorten equipment ROI through increased utilization

- Lower costs through elimination of waste

- Increase customer satisfaction through quality improvement

With Auk Industries, companies are able to unite different business functions with a single, useful metric.

If you want more information, you can visit our blog and website.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation