Humidity and temperature monitoring, applicable in server rooms, offices, greenhouses, warehouses or medicine or food warehouses, etc.

We will take as an example the TSH300v3 sensor that has RS-485 interface and supports Modbus RTU protocol and a temperature range from -10°C to +60°C that can be coupled to most cases.

Installation:

These sensors we can connect them in chain on the walls of the rooms to cover the largest possible area to have a complete reading of large rooms if necessary, for wiring it is advisable to use only UTP/FTP cables with RJ-45 connectors and limit the total length of the cable to 30 m, although it has been shown that longer distances work well, for the power supply of the equipment we do not have to worry because these sensors are powered by the same communication cable, it is recommended to install them at a height of 1. 2 to 1.4 meters above the ground, avoid placing it near windows to avoid exposing it to solar radiation and we must also try to install it in places that have sufficient air circulation.

The last sensor in the chain is connected to the controller, in this case we will use the TCW242 controller which is an industrial grade IoT module that offers monitoring and control for different applications, equipped with Ethernet connection and data acquisition functionality. It has 4 digital inputs, 4 analog inputs configurable to 10V or 4-20mA, 4 relays and RS485 interface that allows us to communicate via Modbus RTU with our sensors, supporting up to 24 Teracom sensors or other manufacturers.

When connecting the sensor(s) we will check the LED indicator:

- If the LED flashes within 1 second, the sensor is working properly.

- If the LED flashes within 3 seconds, the sensor is not communicating with the controller.

- If the LED does not flash, the sensor is not energized.

Once the connection to the sensors is secured, we can communicate our TCW242 via Ethernet to a switch, router, Wi-Fi modem or directly to a PC.

- The TCW242 has the following default network settings:

- IP address: 192.168.1.2, Subnet Mask: 255.255.255.0, Default Gateway: 192.168.1.1

- When entering the IP address of the equipment from the browser you are prompted to log in, by default it is: admin/admin.

- Once inside the web interface we can monitor and configure the input channels, datalogger, relays and alarm system.

It is possible to configure up to 24 independent alarms with 5 different selectable states. Each alarm can be configured using up to 2 limits and hysteresis and can be assigned to a specific channel.

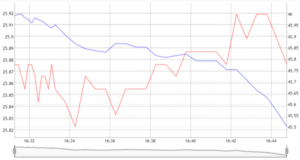

The status of channels and alarms can be displayed through graphs, each graph supports up to 4 channels and 2 dimensions, the color of each calar can be selectable. The information is static and cannot be visualized in real time, to see the most recent information we have to refresh the page and we can export the graph in CSV format.

The device also supports various M2M (machine-to-machine) communication protocols such as SNMP, HTTP API, MODBUS TCP/IP and MQTT. These protocols allow easy integration with other industrial systems and devices, providing users with a wide range of options for data analysis and control. Data analysis and control. Overall, the TCW242 industrial IoT module is a powerful and versatile device that offers advanced monitoring and control capabilities for industrial applications.

Here are examples that highlight the importance of the monitoring system and how this equipment plays a key role in various applications:

- Humidity and Temperature Monitoring for Server Rooms and Data Centers:

The monitoring system plays a critical role in ensuring the uninterrupted operation of server rooms and data centers, where humidity and temperature can have a significant impact on the performance and reliability of IT equipment. Maintaining precise control of these parameters is essential to prevent failures and ensure data integrity. - Environmental Monitoring in Greenhouses, Warehouses and Mushroom Plants:

In agricultural environments such as greenhouses, warehouses and mushroom plants, environmental monitoring is essential to optimize growth and storage conditions. These systems allow continuous monitoring of factors such as temperature and humidity, thus ensuring an optimal environment for growing and preserving products. - Humidity and Temperature Monitoring in Mobile Installations (Telecommunications):

For mobile installations used in telecommunications, maintaining accurate control of humidity and temperature is crucial to ensure reliable performance and prolong equipment life. Constant monitoring allows preventive measures to be taken in the event of adverse changes in these conditions. - Temperature Monitoring for Food and Drug Storage:

In drug and food storage, temperature monitoring is essential to preserve the quality and safety of these products. Monitoring systems provide constant supervision, ensuring that storage conditions meet the standards necessary for the preservation of drug efficacy and food safety.

These examples illustrate how the monitoring system plays a crucial role in a variety of applications, contributing to efficiency, safety and reliability in diverse environments.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation