Introduction.

In the current era, automated processes are crucial in the manufacturing industry, driven by the efficiency and production capacity that machines offer. However, despite their autonomy, constant monitoring is imperative to detect potential errors and analyze machine performance. In this context, remote monitoring emerges as an essential solution to ensure seamless operations.

Preparation.

Before initiating monitoring, it is crucial to define the specific aspects that will be monitored in the process or machine. Once determined, the choice of appropriate sensors is key. These may include pulse sensors, alternating current sensors, voltage sensors, or analog signal sensors. Additionally, a device capable of collecting and recording this information, such as a datalogger or PLC, will be required, enabling data logging and issuing alerts when necessary.

Devices.

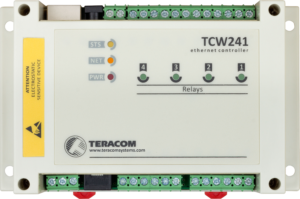

Teracom offers a range of sensors that cater to various needs. Examples include the TDI340 for pulse measurement, the TSC200 for alternating current, and the TSV300 for AC voltage. For data logging, Teracom’s TCW241 is an efficient datalogger, with the capacity for up to 24 loggers and support for protocols such as SNMPV3, Modbus TCP/IP, and NTP.

Monitoring.

Having a centralized space to visualize information is essential. Data acquisition software such as Teracom’s Remote Monitoring Software allows for graphing signals, maintaining historical records, configuring alerts, and providing access to multiple users. Alternatively, solutions like Cimon’s Ultimate Access offer flexibility in interface configuration, with both systems being highly effective for real-time monitoring applications.

Conclusions.

Remote monitoring of automatic manufacturing systems is not only a necessity but also a strategy to optimize operational efficiency. By employing technologies offered by Teracom and Cimon, companies can ensure continuous operation, prevent unexpected failures, and maximize the productivity of their automated processes. Investing in these solutions is not only a proactive measure but an essential step towards excellence in production management.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation