The 200 automated dancing fountains

The Bellagio Hotel and Casino, modeled after the opulent Lake Como Resort in Bellagio, Italy, and known as the pinnacle of luxury in Las Vegas, had a big problem and a small budget to fix it. The Las Vegas landmark’s 200 fountains, which drew crowds from around the world for its spectacular water and light show, was suffering from a technical problem. Some of its automation parts (motor drives installed 11 years earlier) had become obsolete, were no longer for sale, and were no longer available in secondary markets.

Impellers were used to control 220 pump houses (known as Oarsman) at the heart of the fountains, located at the bottom of an eight-acre lake. More than 1,200 jets of water were pumped through the fountains, some of which sent water as high as 460 feet into the air. The fountains are literally an oasis in the desert; fed by a well once used to irrigate the former Dunes Golf Course, formerly on the grounds of the Bellagio Hotel, the fountains use about 10 percent of the water once used by the golf course.

High stakes and low budget

High stakes and low budget

Despite being a superstar attraction in town, the Bellagio Hotel had a small budget to repair its fountains, due to the 2008 recession that affected global tourism. If the equipment couldn’t be fixed, the show wouldn’t go on… Would it still be Las Vegas Las Vegas with still waters at the Bellagio?

Bellagio Hotel engineers had spent years scouring the globe to buy all the old units they could find, and then the supply ran out completely. But the possibility of simply replacing the units with a more current type of unit was quickly ruled out. Any other unit would have a different communication protocol, which would require major changes to the water show’s software and/or hardware system. That would have been risky and costly as it would take a lot of time and testing. In addition, there had to be some sort of mechanism with which to phase in a few units at a time.

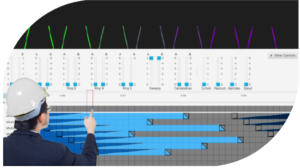

Enter Real Time Automation as a solution provider and partner, who proposed to customize one of RTA’s gateways to emulate the missing units. As a result, none of the water show control software or hardware would require modification! The solution spoke Modbus RTU through an RS232 port to a Rockwell Automation POWERFLEX drive, while communicating with the legacy water source control system via the previous drive’s proprietary serial protocol. The gateway module made the POWERFLEX drive appear to be the old, obsolete drive, allowing for seamless and efficient integration – a true plug-and-play replacement solution.

True plug-and-play unit emulation

With this module, the Bellagio solution was delivered in a matter of days and worked nearly flawlessly during commissioning and dry-run testing on the ground. The custom protocol and logic for the drive was added directly on top of the already established and tested Modbus RTU code. This led to a much shorter test period and very fast progress from beta to production.

Once the onshore testing was completed, the solution had to work well underwater. Installation in this environment was a daunting task that took three days. Divers dove to the bottom of Lake Bellagio and disconnected the Oarsman platform from its grid and power connections. Then, a small crane was floated over the Oarsman, and the 15-foot-tall structure was lifted out of the water and placed on a raft. The decking was left to dry for 24 hours inside the hotel’s outfitting facility. Once dry, the unit solution was installed and tested; finally, the unit was sealed, moved back, lowered into the lake and connected to power and the show controller.

Since the Bellagio fountain shows occur every 15 minutes throughout the day, one day of testing confirmed that the solution saved the dancing waters from disappearing.

If you are working on any application that we can help you with or have any questions, please let us know. We offer free technical support to help you choose the best equipment for your application.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation

High stakes and low budget

High stakes and low budget