Why use a short-wavelength sensor to measure metals at low temperature?

We typically recommend using short-wavelength infrared temperature sensors to measure the temperature of metals, rather than a general-purpose type, because it is more accurate. But why is it more accurate? Here are the reasons.

It has been common practice for decades to measure high-temperature objects with short-wavelength infrared pyrometers. However, these sensors have traditionally been limited to measuring only high temperatures.

Each sensor has a lower limit for its temperature range and, in short wavelength sensors, this lower limit has traditionally been too high to allow the measurement of reflective metals in common industrial applications, such as iron and steel rollers, until recently.

Context

All surfaces emit infrared radiation. Infrared temperature sensors work by measuring the emitted infrared radiation and converting this measurement into a meaningful temperature reading.

The amount of energy emitted depends on the temperature and emissivity of the surface. Nonmetals typically have high emissivity and reflective metals, such as iron and steel, have low emissivity.

At low temperatures, very little infrared radiation is emitted. For a given temperature, low-emissivity materials emit less infrared radiation than high-emissivity surfaces. The lower the amount of radiation detected, the more difficult it will be to achieve an accurate and stable temperature measurement.

Because the amount of measurable radiation is so small, it is traditionally difficult to use an infrared temperature sensor to measure the temperature of reflective metals such as iron and steel at low temperatures.

In general, the shortest possible measurement wavelength should be used to obtain the most accurate measurement. In the past, it was not possible to measure low temperatures with short-wavelength sensors, so users were forced to measure low-temperature metals relatively inaccurately with general-purpose long-wavelength sensors.

Measurement of low temperatures at short wavelengths

Calex has developed a technology that makes it possible to measure temperatures as low as 45°C at short wavelengths (2.0 to 2.6 μm) with improved accuracy compared to general-purpose long-wavelength sensors.

Its sensors are used with great success to measure temperature in welding applications of pipes and roller surfaces in the fabric, laminate, paper, corrugated cardboard, plastic and tire manufacturing industries, among many others.

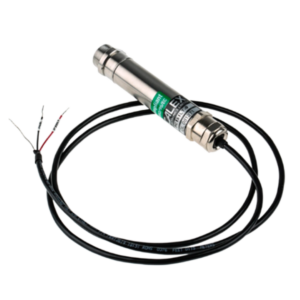

Related Product

PyroCouple infra-red temperature sensor with 15:1 optics.

In Logicbus you can find all the types of temperature sensors to use, for more information contact us!

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation