Is it possible to avoid the deadlock of an industrial process?

Yes, if galvanic isolation and signal conditioning techniques are used properly. Thanks to them it is possible to eliminate almost all forms of interference and risks of failure when the signal from the sensor is acquired by the control unit.

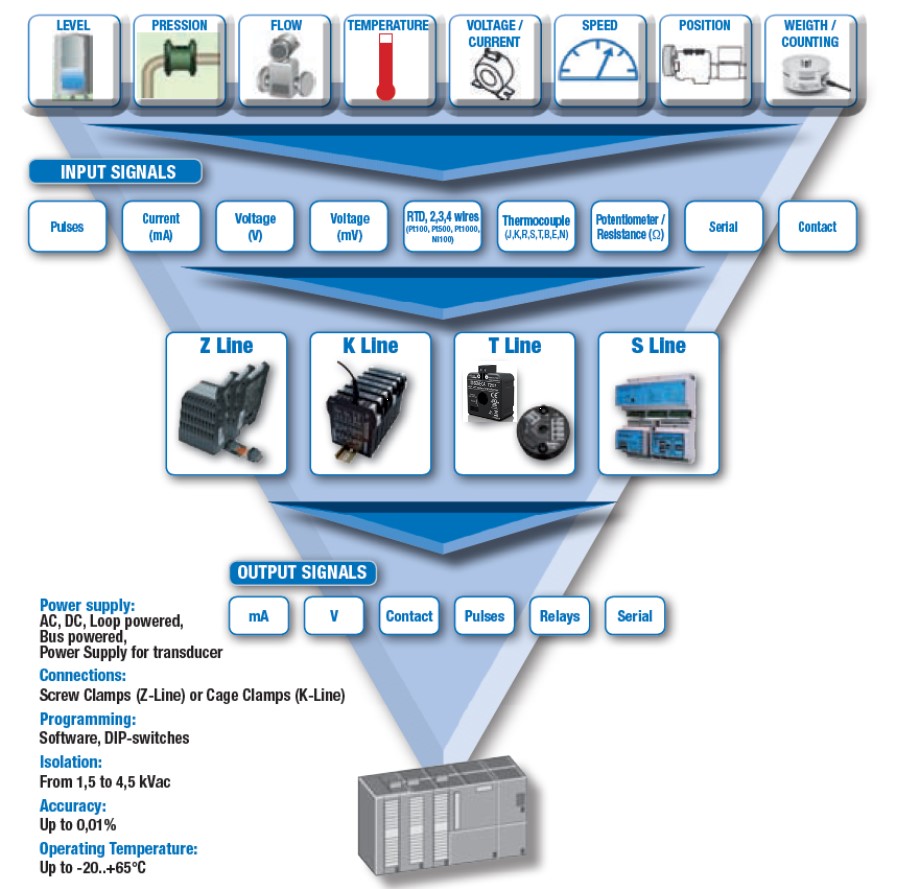

In the context of Data Acquisition “signal conditioning” means an electronic technology aimed at solving the problems of implementation of a common interface between sensors (or actuators) and control units, when the output signals of the sensors are not homogeneous in electrical nature (current, voltage, resistance, etc.), by type (direct, alternating, pulsating, etc.) and by level.

The signal conditioning stage includes all electronic circuits that transform the output signals from the transducers into a homogeneous electrical signal. Typical functions of this stage are high signals attenuations, rectification and leveling of alternating signals, transformation of current signals into voltage, suppression of electromagnetic interference overlaid with the useful signal, galvanic isolation of electronic signal processing devices.

Conditioning circuits are distinguished into active (if they use amplifier components, for scaling or isolation) and passive (such as filters, attenuation circuits, AC/DC converters, current/voltage, etc.).

Signal Conditioning SENECA solutions

SENECA Solutions

Signal conditioning includes filtering, amplification, attenuation, impedance adaptation, galvanic isolation, measurement normalization (current, voltage, resistance, frequency), standardization of measurements from resistance thermometers, thermocouples, thermistors, strain gauges, activation of thresholds, implementation and switching of digital outputs (alarms, transistors, relays) or impulsive.

Signal conditioning devices (converters) can be located in switch cabinets, integrated in sensors, actuators or controllers, on board A/D converters and mutliplexers.

Those proposed by Seneca are modular devices that are independent from automation switchboards (Z-Line, K-Line, S- Line), transmitters for temperature sensors (T120/T121) and current transducers (T201 Series).

The advantages are clear:

Easy installation, cost-effective solution, wide range of converters and applications, in case of error or damage only the converter replacement is required.

Article courtesy of SENECA’s web.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation