As the planet Earth’s population crosses the 8 billion people threshold and more people are living in urban centers, maintaining adequate food production is an ever-growing concern. Furthermore, society demands “organic”, and “pesticide-free” produce, ideally grown locally, close to the urban centers.

Automated vertical farming is a type of agriculture that uses technology to grow crops in vertically stacked layers, usually in a controlled environment. This type of farming increases food production while taking less of an environmental toll than traditional farming, thus benefiting society in several ways. Compared to traditional agriculture, vertical farming has a smaller footprint, uses less water, and yields more crops. Additionally, it requires smaller usage of pesticides and fertilizers and provides a more consistent and reliable food supply.

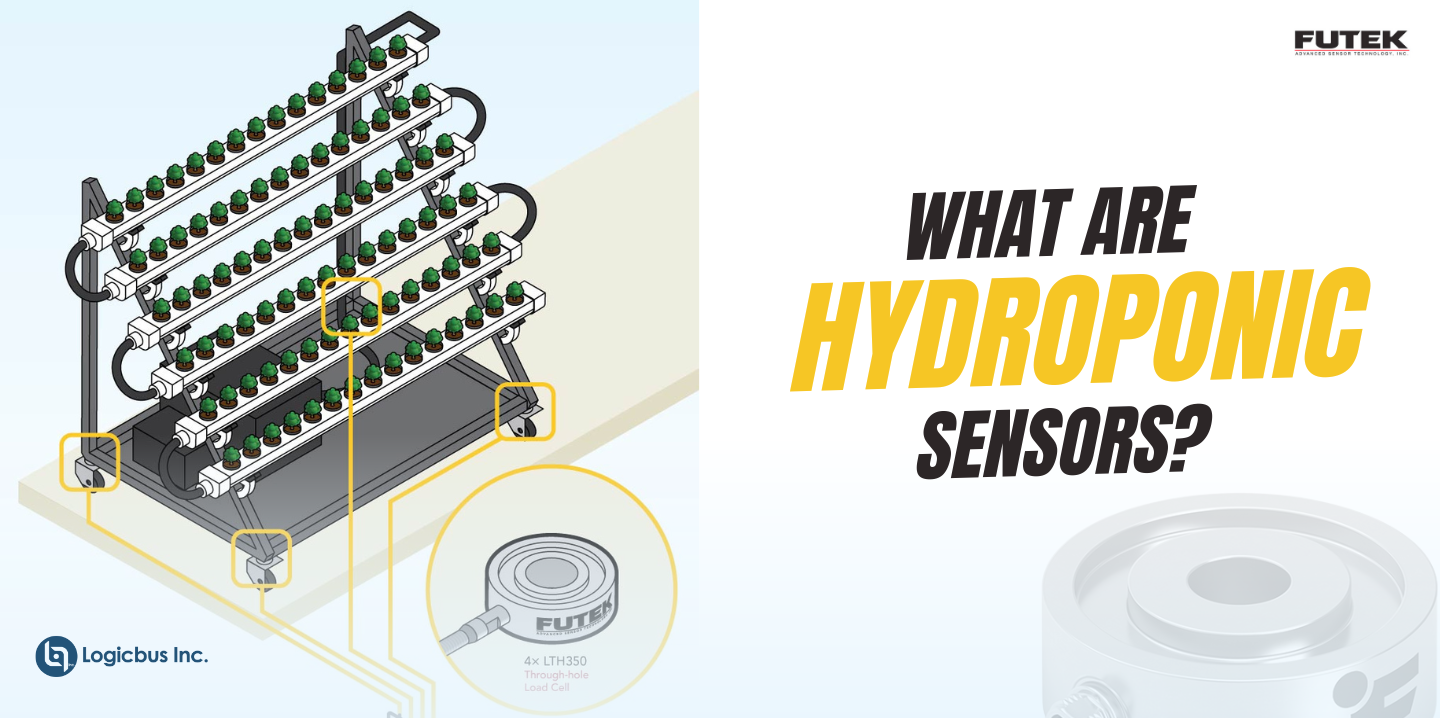

In the context of vertical farming, the Internet of Things (IoT) and Hydroponic Sensors has been a catalyst to the industry, providing innovative solutions for farmers to maximize efficiency and output. Hydroponic sensors, particularly load cell and force sensors, play a critical role in monitoring and controlling the growing environment. These sensors provide real-time data on key parameters such as weight, force, and pressure, enabling farmers to optimize growing conditions for their crops.

One of the main benefits of using hydroponic sensors is that they can help automate the entire vertical farming process. By integrating sensors with a central control system, growers can remotely monitor and control the growing environment. This allows growers to automate tasks such as adjusting the nutrient levels, water supply, and lighting, which would otherwise require significant time and labor.

How can load cell sensors maximize efficiency in automated vertical farming?

How can load cell sensors maximize efficiency in automated vertical farming?

When using hydroponic, precision, productivity and accuracy are key elements to achieve optimal growth and crop yields. Farming is a labor-intensive human activity and load cells and weight sensors helps to automate and optimize of these modern agricultural systems. Some of the key applications of load cell and force sensors :

- Monitoring crop weight: Load cell sensors measure the weight of crops in real-time, providing valuable data to farmers and enabling them to make informed decisions about the growing process;

- Adjusting irrigation and nutrient levels: By monitoring crop weight, load cells can be used to adjust irrigation and nutrient feed levels, making sure that crops are receiving the proper amount of water and nutrients;

- Remote monitoring: IoT sensors enable farmers to remotely monitor remotely the crop and growing environment, reducing the need for presential monitoring.

How it Works

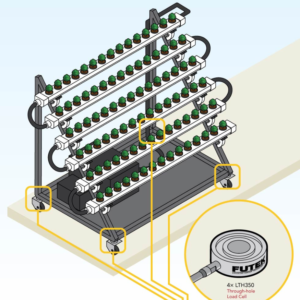

- Four LTH Series Thru-Hole Load Cells have been installed at the base of each leg of the vertical farming structural frame. These compression-based Load Cells will measure the contents of vertical farming system as it increases and decreases. This arrangement helps with load balancing and increases the accuracy of the load measurement.

- The data from each load cell can be collected and streamed through a Summing Junction Box, such as FUTEK’s IAC200 2–4 Channel Summing Junction Box, to a digital display. Both FUTEK’s IPM650 Panel Mount Display and IHH500 Intelligent Digital Hand Held Display are compatible with this testing platform.

- When equipping the platform with either FUTEK’s IPM650 or IHH500, Alarms and/or Relays may be utilized to automate the process.

- Operators may also utilize FUTEK’s USB Solutions – one USB225 Module per load cell – to stream the data directly onto a PC.

- FUTEK’s SENSIT™ Test and Measurement Software can further the testing platform, allowing the operator the ability to collect and live graph all data.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation

How can load cell sensors maximize efficiency in automated vertical farming?

How can load cell sensors maximize efficiency in automated vertical farming?