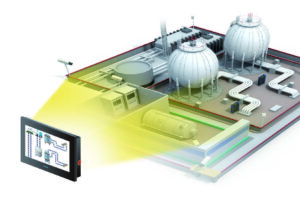

HMIs or human-machine interfaces are panels or screens, currently tactile and in color with which a user or operator can come into contact with a machine, systems, or industrial process, hence their name. Basically, an HMI screen is the means by which a human being can interact with a machine in a simple way using his hands from a centralized point, either through buttons, keyboards, any mouse, sliders, indicators, or any other means of communication. interaction that can be connected to facilitate the user’s work.

HMI types

Given the wide variety of offers that exist in terms of HMI, it is somewhat difficult to classify them but they are mainly divided into 2 large branches:

- HMIs with touchscreen or touch

They are all HMIs that, like smartphones, are touch screens, normally they are in color, but you can find some in black and white, it can also be subcategorized by ranges and prices but this, in the end, should not always be taken As high-end HMIs know how to have as many or more functions than a high-end, the functions that each of this HMI includes allowing to design interfaces, programs, and projects very tailored according to the requirement.

2. HMIs with buttons

They are all HMIs that in order to interact with them, buttons, switches, and any other way that is not by means of the touchscreen are used, they are usually monochrome as they are usually very basic HMIs but they can also be found in color although they are very few, almost all of these know how to be very basic and with very defined functions

Normally the most common HMIs to find in the industry are the color touch screens and they all offer more or less the same characteristics, below we break down some important characteristics:

-

Panel: The size of the diagonal screen is normally measured in inches (the most common sizes being 4.3, 7, 10, and 15 ”) and the relationship between length and something must also be indicated (for example 4: 3)

-

Memory: It is the storage capacity of the HMI where the most common is 128MB

-

Power supply: The connection of the HMIs are powered by direct current through a 24v

-

Communication ports: It depends on each project the communication ports that will be chosen to use the connection, for example, from a PLC to the HMI, the most used in the industry are RS232 / 485, USB, and Ethernet

-

Mounting Type: HMIs are typically panel mounted or slotted locations as they are embedded in a production line or cabinet to avoid manipulation by workers, however, there are portable HMI options.

Applications and Industries

HMIs are usually found in all types of industries, and their applications are very diverse, here are some examples of Industries and Applications:

Industries:

- food and drinks

- pharmaceutical

- manufacturing

- electronics

- automotive

- construction and cement

- aeronautics

- agricultural and forestry

Applications:

Alarm, Trend, Datalog, Email, Camera

-

-

Set the threshold value to monitor system health.

-

Send important messages to recipients via triggered alarm.

-

Attached the alarm information and the camera image captured on site.

-

Data can be exported to assigned location automatically.

-

Security and protection control

-

Protection of intellectual property rights

-

Pay in installments

-

Update user accounts/passwords via external storage

-

On-off delay

Remote monitoring and control

- PLC step

- VNC

- FTP server

- Remote configuration

Data transfer

-

-

Multi-Link, the PLC connected to the master HMI can be accessed via the slave HMI

-

Data transfer from a predefined source to a destination address under user-defined conditions

-

Modbus gateway

-

User defined protocol

-

Currently, with industry 4.0 it is becoming very necessary to have IIoT functions in HMIs, for example, fatek offers these services that you can know more in our web page.

Product Options

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation