What is a load cell and what types are there?

A load cell is a force gauge that has a transducer that measures force and outputs this as an electrical signal.

4 types of load cells:

Pneumatic, hydraulic, strain gauge, and capacitance.

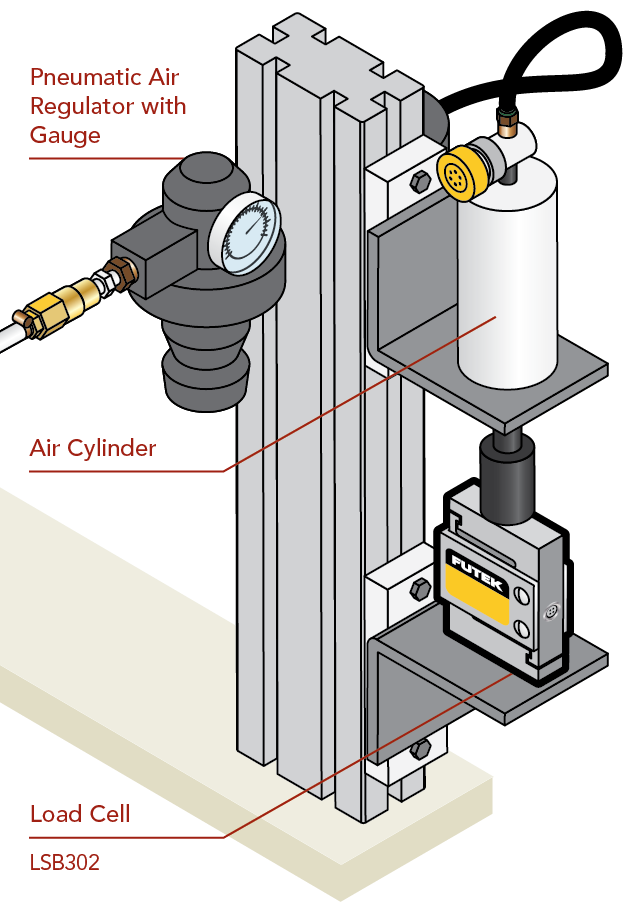

1. Pneumatic Load Cell:

The first thing we need to recognize is that it deals with air pressure. It consists of an elastic diaphragm that is attached to a platform surface. This diaphragm is where the weight will be measured.

An air regulator will limit the flow of air pressure to the system and a pressure gauge. Thus, when an object is placed on a pneumatic load cell it uses pressurized air or gas to balance out the weight of the object. The air required to balance out the weight will determine how heavy the object weights.

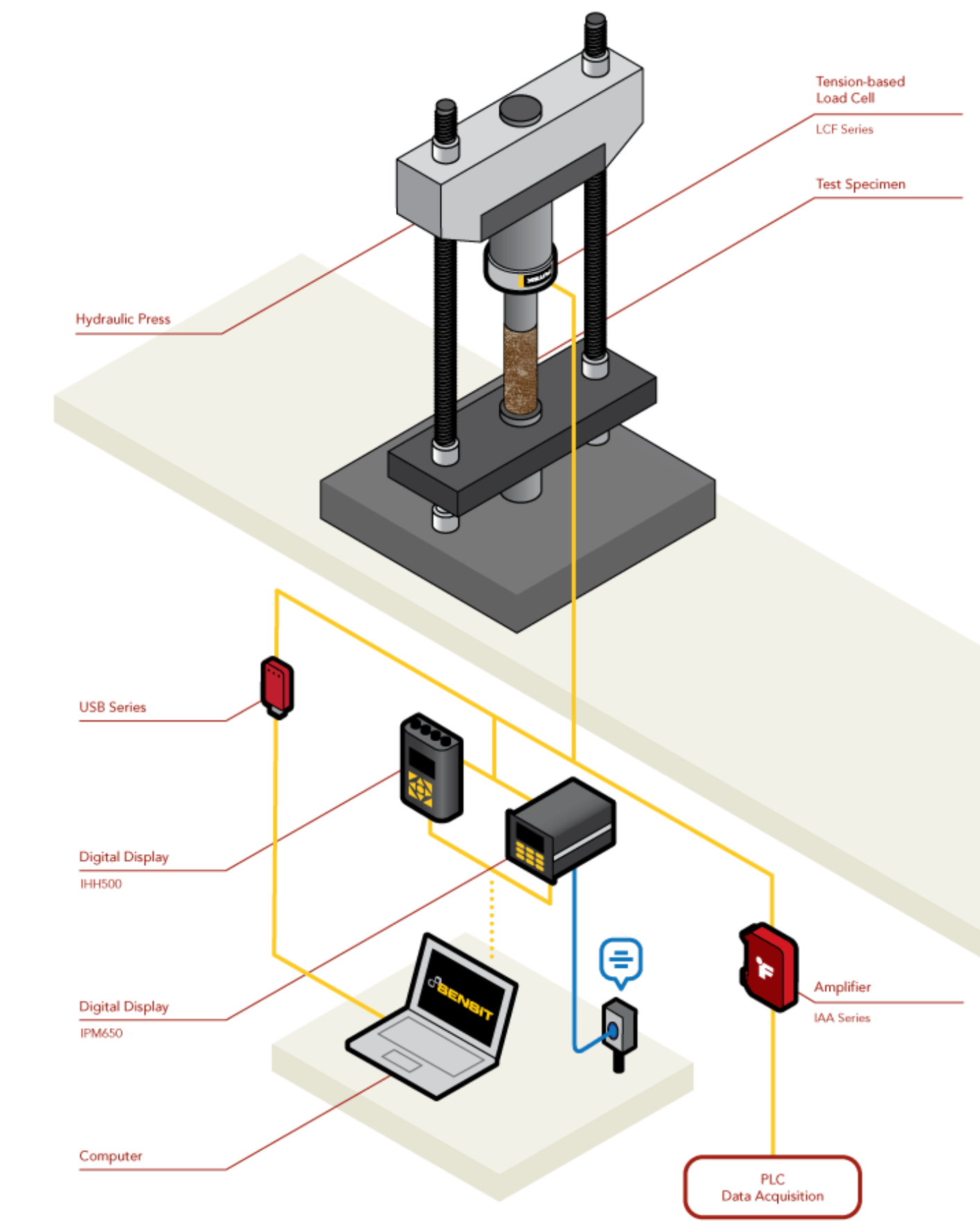

2. Hydraulic Load cells:

The hydraulic load cell will work using fluid: water or oil. These cells are similar to the pneumatic load cells but instead of air, they use the pressurized liquid. They use a conventional piston and cylinder device that conveys a change in pressure It is a force-balance method, acting when the internal filling fluid pressure changes.

3. The stain gauge:

This is the most popular style of the load cell. A strain gauge load cell is a transducer that changes in electrical resistance when under stress or strain.

The electrical resistance is proportional to the stress or strain placed on the load cell, making it easy to calibrate into an accurate measurement.

4. Capacitive load cell:

A system that stores charge. The load cell is made of two flat plates parallel to each other. The plates will have a current applied to them. Once the charge is stable, it gets stored between the plates. The amount of charge stored, the capacitance, depends on how large of a gap between the plates. When the load is placed on the plate, it gives us the weight.

Visit our website

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation