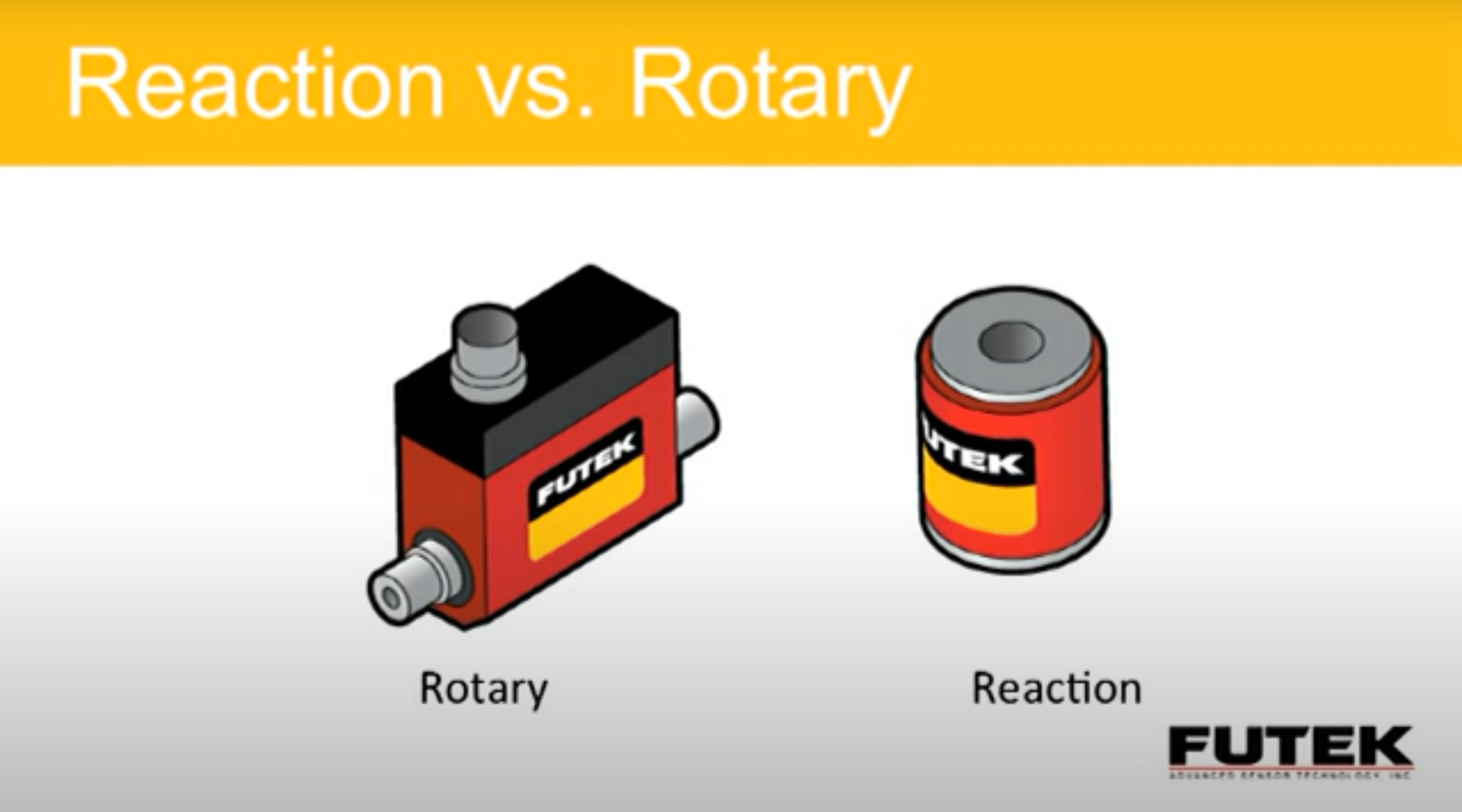

Reaction Sensors vs. Rotary Torque Sensors

What is the difference?

Reaction sensors:

Reaction sensors are not in line with the rotating part. There is no bearing slip rings or varying parts.

Also, they are not recommended for control situation, and they have delayed catching up with rapid changes in the system.

Rotary torque sensors:

Rotary torque sensors line with rotating parts and measure exact work in different rpm rates from 3000rpm to 50k rpm in general because of moving parts like bearing slip rings and variants are high-maintenance. At the same time, they need to be aligned with rotating parts for achieving the best results.

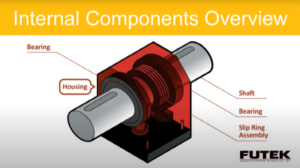

Inside a slip ring rotary torque sensor:

The rotary torque sensor has earrings on both ends and the shaft is sticking out of the housing. Also, you can see the slip ring in the middle of the housing.

The elements inside:

- Bearing:

Bearing rings inside a rotary torque sensor is one of the most critical parts of most rotary sensors. We utilize cross-section bearings for our product, which makes them as compact as possible for a certain capacity. If you use low-quality bearings the shaft hits up and miss your measurement and lifespan of the sensor

- Tip for the reader:

Figure out where the bearing come from. Are they quality bearings?

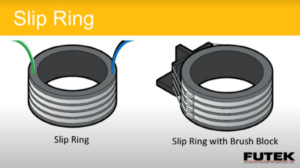

- Slip Ring:

Above we can see the slip ring assembly. On the left side, you can see the slip ring which sits on the shaft and on the right side you can see the slip ring and a brush block the brush block

Seats under the housing when the shaft rotates, the slip ring assembly transmit this electric signal and the supply voltage from housing to the rotating shaft.

On the right hand, as we can see there is a contact between the brush block and the slip ring because of this contact the RPM rate directly affect the lifespan of slip ring assembly the higher rpm you go you need to replace the slip ring assembly earlier because of wear and tear of the unit.

If you are working on any application that we can help you with or have any questions, please let us know. We offer free technical support to help you choose the best equipment for your application.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation