About the Customer

China’s high-speed rail is the world’s largest high-speed railway network, and its 350km / h operating speed is also the fastest in the world. This is the result of railway construction that brings together the most advanced engineering technology.

The operation of the high-speed rail is not only a breakthrough in hardware construction, but also in economy, culture and daily life.

In addition to promoting the economic development of the regions along the route, narrowing the gap between urban and rural areas, it also enhances the competitiveness of urban areas and accelerates the upgrading and transformation of manufacturing industries.

The high-speed rail reduces the inter-city travel time, just like a “space revolution” in which the distance between the two places is greatly reduced.

Cross-regional transportation and travel have become handy and are no longer out of reach, deepening cultural exchanges and interactions in various regions, and thus changing people’s lifestyles and habits.

Requirements

With the progress of the times, the demand for sanitation and environmental protection is increasing. The out-of-date sanitary system that directly discharges the dirt outside can no longer meet the needs. A new sanitation system that can store the dirt in the collection tank at the bottom of the cabin is required.

And in order not to affect the speed of the train, this system must avoid excessive water usage to reduce weight.

Solution

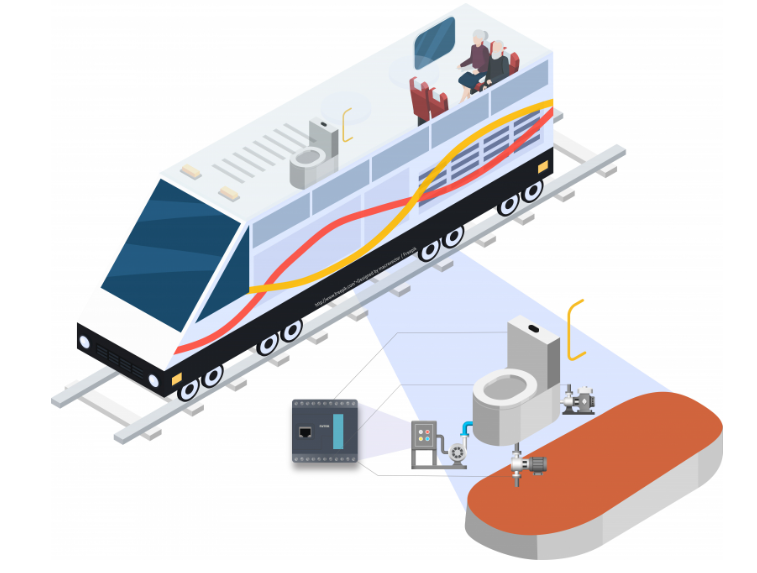

In order to greatly reduce the water consumption during flushing, the vacuum collection method is adopted.

The extremely large air pressure difference is used to extract dirt and at the same time release a small amount of water for surface flushing. The extracted dirt will be stored in the collection tank at the bottom of the cabin and blocked by a closed partition to prevent smell from diffusing.

When pressing the flush button, it will on the PLC input and quickly trigger the vacuum generator from the output, and the vacuum starts to form in the sewage collection tube; then the compressed air passes through the air filter and air pressure regulating valve and enters the separator of the pneumatic pump.

The partition is moved down, the water under the pneumatic pump is pressurized, and then enters the toilet flushing pipe along the pipeline, so that the flushing nozzle flushes the toilet, and the dirt is completely flushed into the dirt tank.

After flushing the toilet, the diaphragm of the pneumatic pump moves up due to the action of the spring until the original position is restored, the vacuum generator stops working, and the thimble filter also opens. At this time, the filtered water enters the diaphragm of the pneumatic preparing for the next flush,and the compressed air in the pneumatic pump is discharged through the air release pipe.

Results

“Save nearly 70% of water consumption” “Significant reduction in energy and water usage” “The air is fresh again along the way”.

System Topology

Related Product

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation