In the world of industrial automation, the terms PLC, PAC and IPC are launched as if they were interchangeable. The problem is that in many ways they are. And, as technologies advance across all three device categories, their unique features and benefits converge and their differences become less noticeable.

So how are these three technologies different?

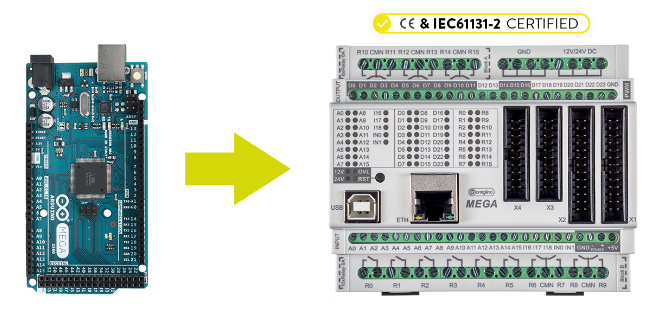

The evolution of controllers

Today, PLCs automate processes, machine functions, and even entire production lines within manufacturing plants.

They provide several advantages over previous automation systems:

- They tolerate the industrial environment.

- Are more reliable and more compact.

- Require less maintenance than relay systems.

- They also use a simple programming language and are easily extensible with additional I/O modules.

Process automation controllers (PACs) were introduced in the early 2000s. They can be described as industrial controllers that combine the functionality of a PLC with the processing power of a PC. However, without a standard definition, the distinction between PAC and PLC remains blurred.

High-end PLCs incorporate many of the attributes that were once unique to PACs: standard programming languages, the ability to expand functionality through add-on modules, connectivity to various bus systems, and monitoring and control of a large number of I/O.

So what’s the difference?

Unfortunately, the differences between PLC, PAC and IPC are still shades of gray instead of black and white.

That said, the simplest way to look at these three devices is: a PLC can be thought of as the standard base controller; the PAC is similar to a PLC but with additional features; and, the IPC runs the same software found in a PAC but with all the features of a personal computer.

Let’s take a closer look

-

PLCs

Have a small footprint and typically use ladder logic to control discrete machinery or processes. They offer a wide range of features, from analog I/O to advanced communication protocols, and are relatively inexpensive, making them the go-to choose in small-scale projects. The most advanced PLCs are capable of remote I/O and motion control.

-

PACs

Are best suited for more complex automation solutions that deal with advanced process control, motion control, visualization and more. In addition, PACs use exception-based logic instead of ladder-based logic. They are larger and much more expensive than PLCs, but provide greater scalability, support a large number of control I/O, offer the ability to add other PACs for redundancy, and much more.

-

CPIs offer

The same advantages as PACs, but with even more capabilities. They are increasingly suitable for industrial environments on both the hardware side (more robust construction) and the software side (more applications). IPCs are used for anything that needs the CPU power and versatility of operating systems like Windows or Linux. Some are used as a control center or database center for other control devices, such as PLCs and PACs.

Which controller is right for you?

The clean and tidy answer is: it depends. One industry professional suggested, “If you’re looking for a standalone machine, a PLC may be the right choice. But if you also want to address motion and security or control remote I/O, a PAC is often the way to go. And if you need to add additional features and software beyond what a PAC can do, that’s when you could start looking for an IPC.”

Price will always be an important determinant. However, are you talking about start-up costs or lifetime costs? In some cases, a large upfront investment may be cheaper in the long run when considering future scalability needs and analytical and data mining capabilities for continuous process improvement.

Ultimately, the final selection will be determined by a variety of factors that apply to your specific application, including functional requirements.

RTA specializes in manufacturing easy-to-use connectivity products, including industrial protocol gateways, integrated source code stacks, and custom OEM solutions. Our products are used by control engineers in factories around the world and are backed by our industry-leading Enginerd® technical support to help you save time, money and hassle.

They also have a 5-year warranty, are made in America and are always in stock, ready to ship the same day you place an order.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation