Several solutions in one design

The Nano force sensor unique M1-threaded double-sided mounting provisions allow it to measure both tension and compression, an industry breakthrough for a sensor this small. It can also be mounted to only measure compression.

Unique mounting flexibility

In addition to the front end mounting provisions, the Nano also features a patent-pending thru-hole design, which mounts over a shaft as a monolithic structure.

Multiple measuring capabilities

The in-line micro rod/rope thru-hole configuration with an M1 mounting provision allows for both tension and compression force measurement.

Bottom-mounted compression

In this configuration, the sensor is installed onto the mounting plate and top. When integrated this way, the Nano measures compression force only.

Small package, mighty performance

The subminiature size doesn’t compromise the Nano’s performance. It meets FUTEK’s highest accuracy standards and meets the benchmark for precision for all our products.

- Height: 5mm

- Width: 4mm

- Weight: 0.5g

- Max Capacity: 50 Lb

Low power consumption

The Nano is an energy saver. Its 1000 Ohm resistance full-bridge strain gauge instrumentation supports low power consumption, opening the door for battery-powered mobile device applications as well energy-conscious configurations with large quantities of sensors per system.

Born ready

As soon as you turn it on, the Nano force sensor is ready to go. Its full bridge instrumentation allows for 5V excitation without extensive warmup time, a key capability for applications where system readiness is a critical factor.

Made for R&D

A Flextail adapter converts the Nano’s OEM-friendly four conductor flex cable into a conventional cable, eliminating the need for additional electronics in initial development integration.

High resolution and accuracy

Featuring 5VDC excitation, which is powered by the full-bridge instrumentation, the Nano integrates seamlessly with USB and SPI electronics that ensure high resolution and accuracy.

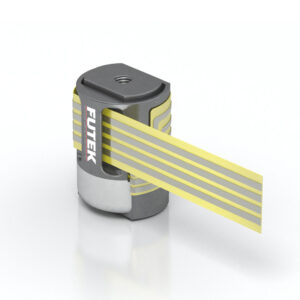

Powerful packaging

An innovative, patent-pending, non-active packaging design keeps force measurements accurate in highly dynamic environments by isolating the interconnect cable from the active sensing element. It also ensures high durability of the interconnect, minimizing potential for damage during setup.Corrects off-center loading.

The Nano’s double sided instrumentation compensates for eccentric loading conditions and tolerance stackups, improving compatibility with mechanical systems.

-

Built to scale

Assembled using FUTEK’s proprietary micro-welding technology, the Nano force sensor robust aerospace-grade alloy sensor body and enclosure assembly are laser-welded to achieve an extremely robust construction. This assures high process reproducibility, scalability and compatibility with the most dynamic, high vibration, shock, temperature, or chemically intensive environment.

-

High-natural frequency

In additionally, the Nano sensor’s low flexure design delivers unmatched high natural frequency of 98kHz, providing an ultra fast response (30-40x faster than larger/comparable solutions). Natural frequency is directly related to the cycle time capability of the robotic system. Nano’s ultra fast response will benefit cycle time reduction and result in an overall higher throughput of the automated system.

-

Ultra low deflection

One of the highlights of the Nano’s performance is its ultra low deflection (1-10,000 in.), which supports high accuracy control due to its very low effect on the structural rigidity of the system.

If you are working on any application that we can help you with or have any questions, please let us know. We offer free technical support to help you choose the best equipment for your application.

Visit our website:

www.logicbus.com

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation