In this blog, we will discuss signal conditioning, which is the fundamental function, where it is applied, how important it is used in load cells, and will introduce a brand that Logicbus provides called SENECA.

Signal Conditioner Definition:

Signal conditioning is a data acquisition process that is carried out by an instrument called a signal conditioner.

Introduction:

The output signal of the load cell of a general measurement system must be processed in a suitable way for the next stage of the operation. The signal can be, for example:

- Being small, and it would be necessary to amplify it

- May contain interference to eliminate

- Be non-linear and require its linearization

- Be analog and require digitalization

- Be digital and convert it to analog

- Being a change in the value of resistance, and convert it to a change in current.

- Be a consist of a change in voltage and convert it into a change in current of suitable magnitude

- And many other modifications.

All these modifications are generally referred to as signal conditioning.

1. Signal conditioner:

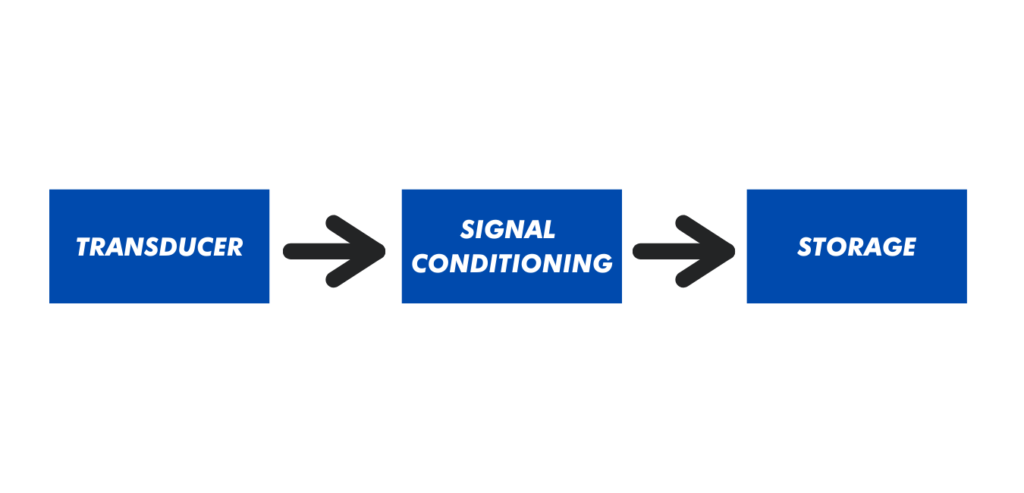

When we want to carry out a measurement, the main thing is to have a transducer that can transform the physical measurement into an electrical measurement. That electrical measurement must be conditioned. To understand this, conditioning a signal means performing the following process: Converting the signal, modifying the signal level, linearizing for a response, and finally filtering the signal. A signal conditioner is a data acquisition step that is carried out with a device that can convert one type of electronic signal to another. Its main objective is to convert a signal that can be difficult to read and convert it to another format so that it has an easy way to read the acquired data. Key technologies for signal conditioning improve overall by obtaining good performance from the data acquisition system.

Most of these signals require some form of preparation before they are digitized. For example, the signals of a thermocouple, these signals provide very small voltage levels that must be amplified before they are digitized. We can mention other sensors, such as resistance temperature detectors (RTD), thermistors, strain gauges and accelerometers, all this technology that requires preparation work involves a signal conditioner.

Most of these signals require some form of preparation before they are digitized. For example, the signals of a thermocouple, these signals provide very small voltage levels that must be amplified before they are digitized. We can mention other sensors, such as resistance temperature detectors (RTD), thermistors, strain gauges and accelerometers, all this technology that requires preparation work involves a signal conditioner.

2. Stages of Signal Conditioning

A. Amplification

At this point it is done when considering that the typical signal output level is too low. This is done with the help of an op amp, the which is required from a series of important input characteristics for load effects can be minimized at the exit sign.

B. Filtering

This point consists of eliminating certain frequency bands of a signal, and opens them doors to others for transmission. The frequency interval that passes a filter is known as the passband, the interval that is not allowed to pass is known as a rejection band and the boundaries between both intervals is known as frequency of outages.

C. Linearization

At this point is to get a signal output that can vary linearly with the variable to be measured, an example of its use is in the case of a sensor where its output varies exponentially with respect to the variable to be measured.

D. Signal conversion

This point tells us that it is necessary convert one type of variable to another, a example, there are a certain amount of sensors that vary their resistance as consequence of the variation, in this case a circuit is required that can convert these resistance changes in a voltage or in a stream.

E. Multiplexers

It is a circuit that has the power to receive data that comes from various sources, when selecting a channel input, can produce an output corresponding to only one of them, in this case, in the term of data acquisition, consists of taking data from the sensors and put them in a computer to be able to be prosecuted.

3.Load cell transducers on Scales

A load cell is a transducer that is used to convert a force into a signal electrical. For example in digital scales, since for them, the load cell is one of the more important elements, since these cells load are in charge of translating the force of voltage signal (analog load cell), the analog load cell with gauges potentiometric is the one most used in the bathroom scales.

A load cell is usually composed of 4 strain gauges that are connected in a bridge configuration of Wheatstone.

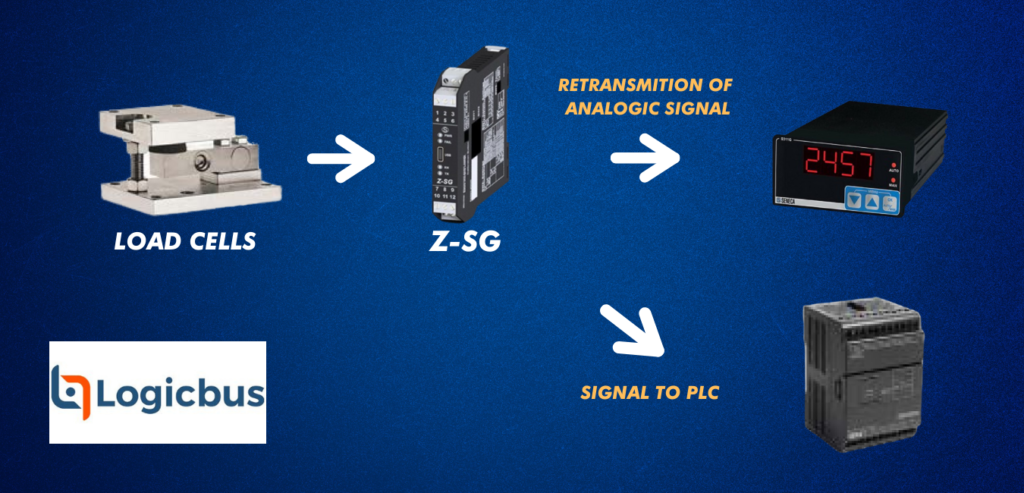

Wheatstone Bridge is an arrangement of four resistors to determine the value of a unknown resistance and is used commonly in load cells. The signal obtained is millivolts and has to be amplified to voltage, current 0 ~ 20m Amp or 4 ~ 20m Amp and even to one signal analog with an instrumentation amplifier via RS232 or RS485 ports. The output of the the transducer is taken to perform calculations necessary to obtain the force applied to the transducer.

The signal from the cell, gauge, or load cell is leads to an analog-digital display for convert it to a digital numeric value, this value is multiplied by a factor to convert it in weighing units such as kg, lb, etc; the scales measure the force generated by an object and since Force equals Mass times acceleration (F = m.a) and the acceleration is a constant (the earth’s gravity) can be say that Mass is directly proportional by force. The factor is the one that fits in again calibration and in this way gives us an exact data.

4. CONCLUSION

A signal conditioner for cell use strain gauge is actually a strain gauge amplifier, which is used to condition signals from bands strain gauges. These strain gages are mounted inside the cell and measure the force at traction or compression, by deformation of said, bands.

The available formats are different, although the most common are the electronic ones on DIN rail, there is also the availability of wheatstone bridge displays, not forgetting Scalable rack-mount options for simultaneous acquisition of multiple bands strain gauges. When used for strain gage, these modules always condition full bridge. If want to rehearse with bands strain gauges, it is better to use specific modules that allow us to complement the bridge, balancing and calibration automatically.

Visit our website:

https://www.logicbus.com/Z-SG_p_4195.html

Contact us

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation