Fiber optic sensing has revolutionized the way we monitor and measure various physical parameters. From temperature and strain to pressure and acoustic waves, fiber optic sensors can provide accurate and real-time data in a variety of applications.

But what makes fiber optic sensing so effective? One key factor is the use of contrast. In this article, we will explore the importance of contrast in fiber optic sensing and how it contributes to the success of this powerful technology.

The Role of Contrast in Fiber Optic Sensing

Contrast is a crucial element in fiber optic sensing as it allows for the detection and measurement of small changes in physical parameters. In simple terms, contrast refers to the difference between the light signal that is transmitted through the fiber and the light signal that is received at the other end.

Optical Sensors and Contrast

Optical sensors are the key components of fiber optic sensing systems. They are responsible for converting physical parameters into changes in light signals that can be measured and analyzed.

The use of contrast in optical sensors is essential as it allows for the detection of small changes in the physical parameter being measured. Without contrast, these changes would be undetectable, and the accuracy and reliability of the sensor would be compromised.

Distributed Fiber Optic Sensing and Contrast

Distributed fiber optic sensing (DFOS) is a technique that allows for the measurement of physical parameters along the entire length of an optical fiber. This is achieved by using a special type of fiber known as a “sensing fiber” that is capable of detecting changes in physical parameters at multiple points along its length.

Contrast plays a critical role in DFOS as it allows for the differentiation between the light signals that are transmitted and received at different points along the fiber. This enables the accurate measurement of physical parameters at specific locations, providing a detailed and comprehensive understanding of the environment being monitored.

How Contrast Impacts Fiber Optic Sensing for Production Lines

Contrast plays a crucial role in the effectiveness of fiber optic sensors used on a production line. Here’s how contrast impacts their effectiveness:

1. Signal-to-Noise Ratio (SNR)

Contrast helps in achieving a high signal-to-noise ratio, which is essential for accurate and reliable sensing. A high contrast between the transmitted and received light signals allows for better detection of changes in physical parameters. This reduces the impact of noise or interference on the sensor readings, resulting in more precise measurements.

2. Sensitivity and Accuracy

By maintaining a high contrast, fiber optic sensors can achieve higher sensitivity and accuracy. The ability to differentiate between different light signals enables the sensor to detect even slight changes in physical parameters. This level of sensitivity is crucial for monitoring and controlling processes on a production line, ensuring optimal performance and quality control.

3. Spatial Resolution:

Contrast also affects the spatial resolution of fiber optic sensors. A higher contrast allows for better differentiation between signals received at different points along the fiber, enabling more precise location-specific measurements. This is particularly important in applications where it is necessary to monitor specific sections or components of the production line.

4. Dynamic Range:

Contrast influences the dynamic range of fiber optic sensors. A wider dynamic range allows the sensors to accurately measure a broad range of physical parameters. This is especially important in production line environments where there may be significant variations in the parameters being monitored.

On a production line, contrast ensures a high signal-to-noise ratio, improves sensitivity and accuracy, enhances spatial resolution, and expands the dynamic range of the sensors. These factors contribute to reliable and accurate monitoring, control, and quality assurance in production line processes.

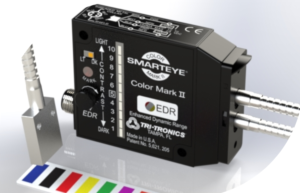

When it comes to conquering low or difficult contrast sensing challenges, Tri-Tronics sensors are the unrivaled choice. Our extensive selection ensures you’ll find the ideal fiber optic sensor tailored to your needs.

Fiber Optic Sensor Considerations for Detecting Contrast

While selecting the right equipment and properly maintaining it can help with proper contrast sensing, contrast can also be baked into the design of products to further boost detection accuracy. Manufacturers can design their products for compatibility with fiber optic photoelectric sensing systems by considering the following factors:

Quality of Optical Components

The quality of the optical components used in your sensing system can have a significant impact on the contrast of your measurements. High-quality components, such as optical fibers and connectors, can help minimize signal loss and maintain high contrast throughout the sensing process.

Proper Calibration and Maintenance

Proper installation and handling of your fiber optic sensing system are also essential for maintaining high contrast. Any damage or misalignment of the optical components can lead to signal loss and affect the accuracy of your measurements.

How to Achieve High Contrast in Fiber Optic Sensing

While selecting the right equipment and properly maintaining it can help with proper contrast sensing, contrast can also be baked into the design of products to further boost detection accuracy. Manufacturers can design their products for compatibility with fiber optic photoelectric sensing systems by considering the following factors:

Optical Interface

The design should include a suitable optical interface that allows easy connection with fiber optic cables. This could involve using standardized connectors, such as FC, SC, or LC, to ensure compatibility with a wide range of fiber optic sensing systems.

Wavelength Range

Manufacturers should consider the wavelength range of the fiber optic sensing system they are targeting. This will help them choose the appropriate light source and optical components that can operate within that range, ensuring compatibility with the sensing system.

Signal Modulation

Some fiber optic sensing systems use modulation techniques to extract measurement data from the reflected or transmitted light. Manufacturers can design their products to support these modulation schemes, enabling seamless integration with the sensing system.

Signal-to-Noise Ratio

Designing products with low noise characteristics can improve the performance of fiber optic sensing systems. Manufacturers should focus on minimizing noise sources within their products, such as electrical interference and optical reflections, to enhance compatibility with the sensing system.

Power Requirements

Manufacturers should consider the power requirements of the fiber optic sensing system when designing their products. Providing power-efficient components or designing for low power consumption can ensure compatibility and maximize the system’s performance.

Environmental Considerations

Fiber optic sensing systems are often used in challenging environments, such as those that contain high temperatures or harsh chemicals. Manufacturers should design their products to withstand these conditions, ensuring long-term compatibility and reliability.

By taking these factors into account during the product design process, manufacturers can optimize compatibility with fiber optic photoelectric sensing systems and provide reliable solutions for their customers.

sales@logicbus.com | support@logicbus.com | +1 619 616 7350 | Start conversation